Our Simulation Services:

- Computational Fluid Dynamics (CFD)

- Finite Element Analysis (FEA)

- Discrete Element Modeling (DEM)

CFD simulation:

Computational Fluid Dynamics (CFD) is a powerful tool that uses numerical models to simulate and analyze the behavior of fluids (liquids and gases) within a system. It allows engineers to visualize how fluids move, interact with surfaces, and affect the performance of industrial equipment. CFD can simulate complex real-world conditions that are difficult or impossible to test physically, providing valuable insights into optimizing designs and processes.

Key applications of CFD in engineering:

- Building Design: CFD provides visualization of airflow, heat distribution, and contaminant movement in the design of HVAC and ventilation systems. It enables virtual prototyping to foster creativity and innovation. It also helps assess existing buildings, identify issues, and recommend improvements.

- Product Design: CFD can be used to simulate fluid interactions, heat, and mass transport in a wide range of applications, optimizing designs for better performance, reliability, and efficiency. It helps identify potential issues early in the design phase, reducing costly modifications later.

- Industrial Air Movement: Design and optimization of ventilation, heating & cooling systems, dust and contaminant transport, drying processes, etc.

- Wind Engineering: Wind loading, wind comfort, re-entrainment studies for building exhausts, cooling tower plumes, condenser heat release.

Selected CFD projects

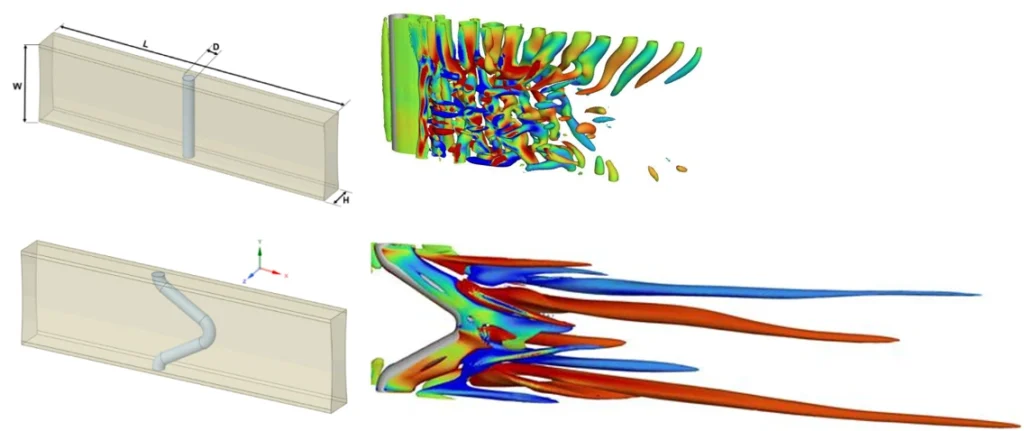

- The zigzag vortex generator showed distinct flow pattern compared to a straight one.

- The zigzag vortex generator reduced drag and enhanced heat transfer over the straight one.

- The significant drag reduction was attributed to suppressed vortex shedding, whereas the heat transfer enhancement was due to the formation of streamwise vortex loops

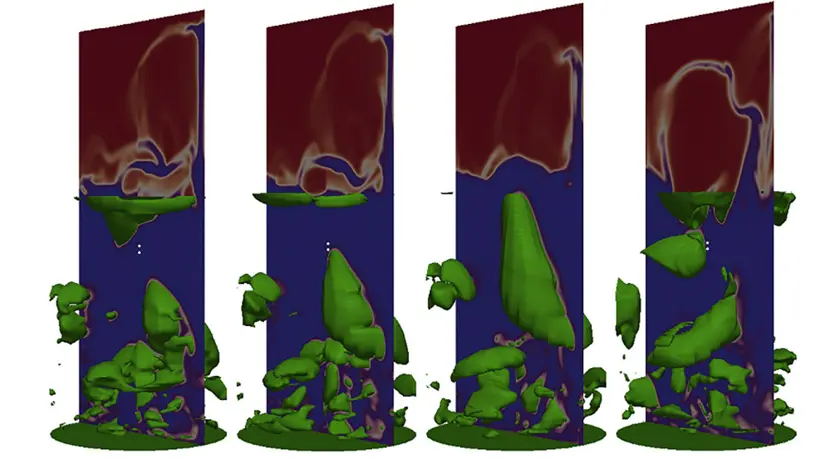

- The Proper Orthogonal Decomposition and the swirling strength criterion are applied to the particle flow fields predicted by a “two-fluid model” of a cylindrical bubbling bed.

- The dominant spatio-temporal patterns of the particle phase are identified and analyzed.

- The dominant fluctuations in the particle volume fraction occur in the central and upper part of the bed, where the larger bubble structures form, and also at the bed surface, where bubbles burst.

- The particle vortical motions in bubbling beds are characterized by their extended and flat structures.